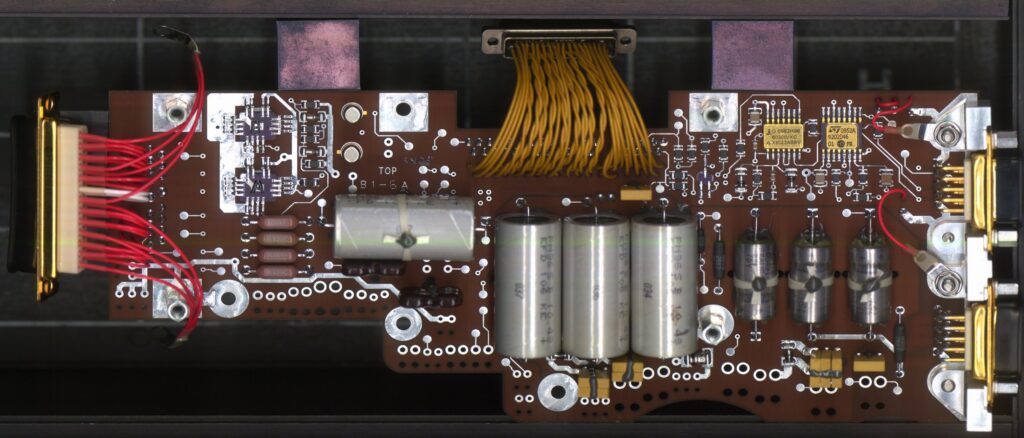

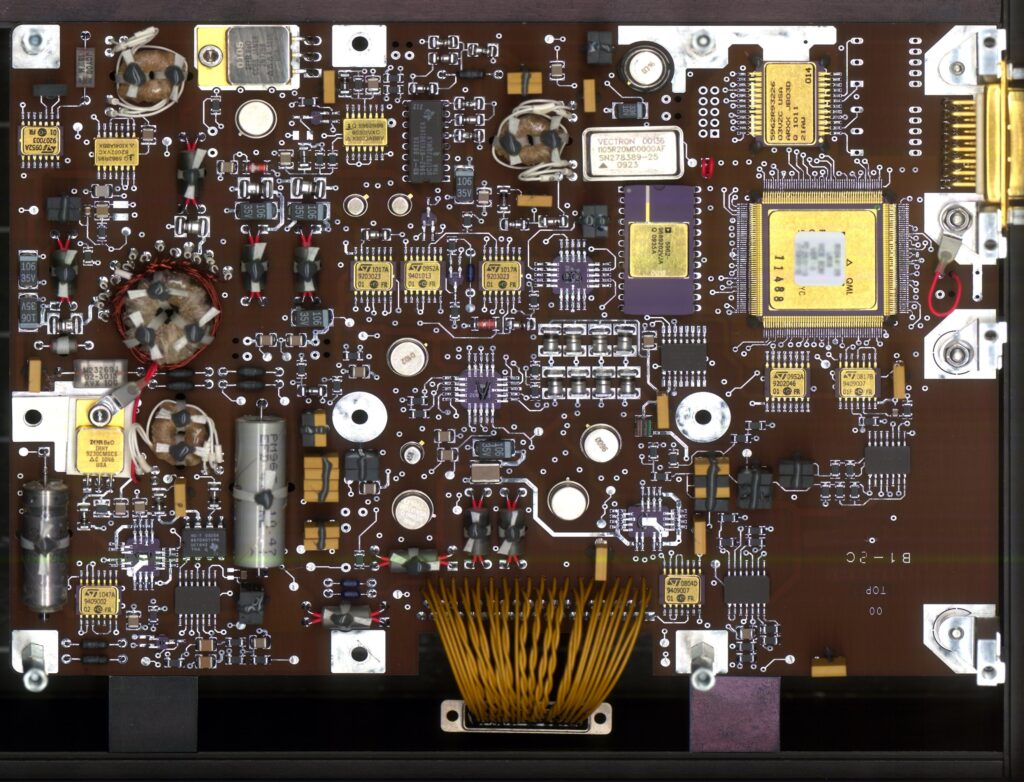

Spur Electron has a flexible and wide ranging ESA and IPC approved skill set for Space hardware assembly

Spur Electron continues its long history and heritage working to the exacting standards required by the European Space Agency (ECSS Level) and Defence Industry (IPC Level).

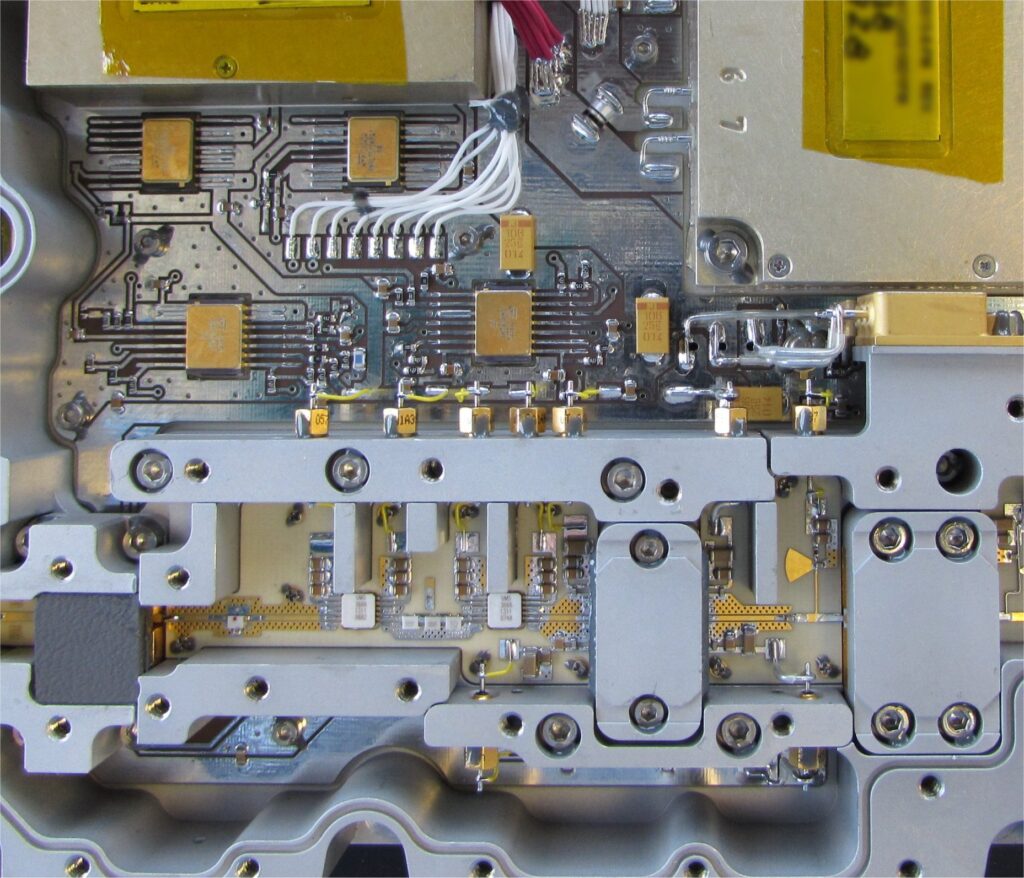

Within the ISO Class 7 clean room, our ESA certified technicians and inspectors, trained by our own in-house ESA certified trainer, provide cost effective assembly. They combine semi-auto assembly, utilising state of the art vacuum vapour phase reflow technology and hand mounting techniques optimised to deliver quality and reliability.

The European Space Agency ECSS standards require all component types selected for use within Space hardware to be verified as acceptable prior to placement. Spur has developed a considerable library of such components, which can be utilised by our clients to reduce cost and schedule risk.

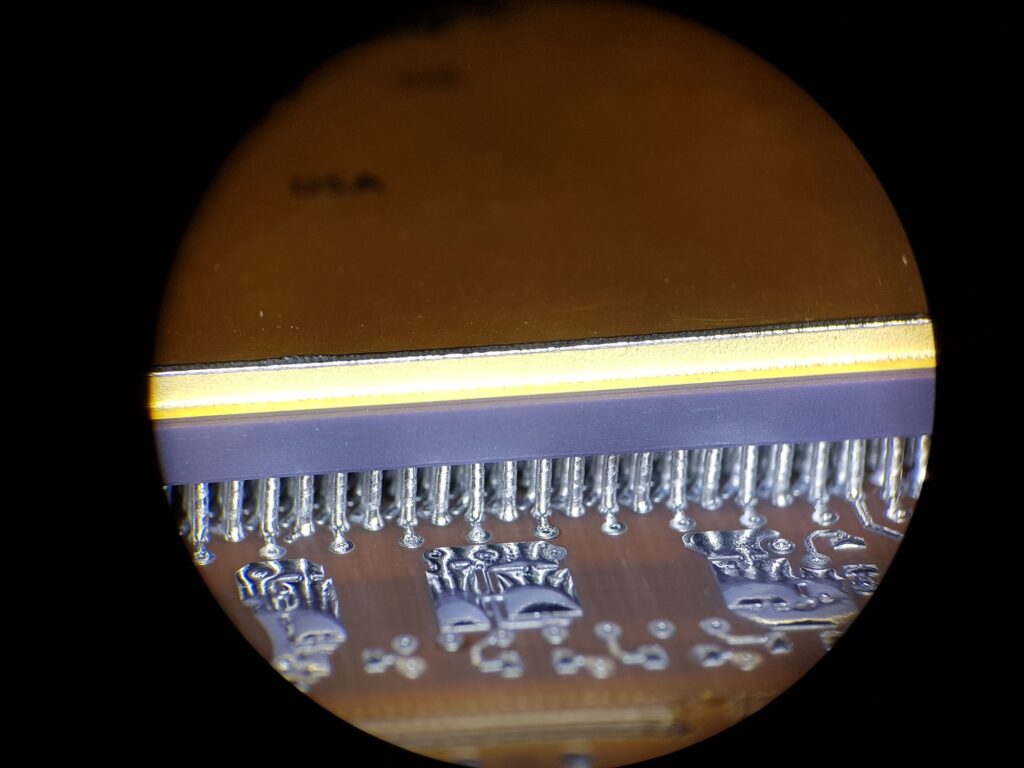

Clients using high pin count devices in the form of Ceramic Column Grid Arrays (CCGAs) is increasing and Spur have been at the forefront in the development of the necessary specialised processes to place and repair these devices, initially developing them for the Actel 624 pin device. Spur have now demonstrated their ability to place and repair Virtex 4 & 5 devices (1140 & 1752 pins respectively).

Spur Electron have a history of continuous investment in the equipment necessary to support our technical expertise, as demonstrated by the recent acquisition of a CCGA/BGA rework station, a state of the art vacuum vapour phase machine and hot air re-work station for passive components.

Spur Electron’s expertise is ready to turn your designs into first class Spacecraft hardware.