Spur Electron Component and Materials Assessment Laboratory

The Spur Electron Laboratory combines analytical skills, expertise and facilities for component and materials assessment both in support of our service offerings and as an independent centre of excellence to the Space, defence and commercial industry.

Means Of Testing We Offer:

COMPONENT & PCB ANALYSIS

- Optical inspection

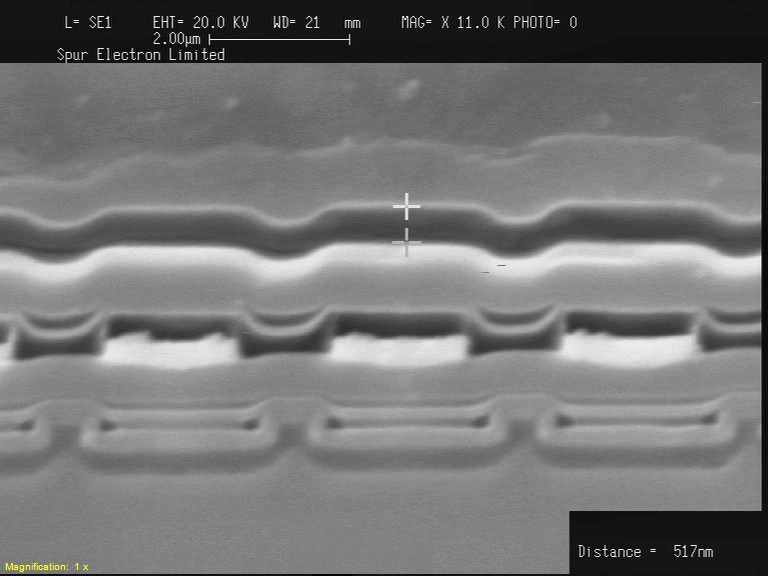

- Scanning Electron Microscopy (SEM)

- Energy Dispersive X-ray (Materials Analysis)

- Radiographic (X-ray) Inspection

- Hermeticity Testing

- Chemical/Mechanical Decapsulation

- Chemical Etching

- Wafer Lot Acceptance

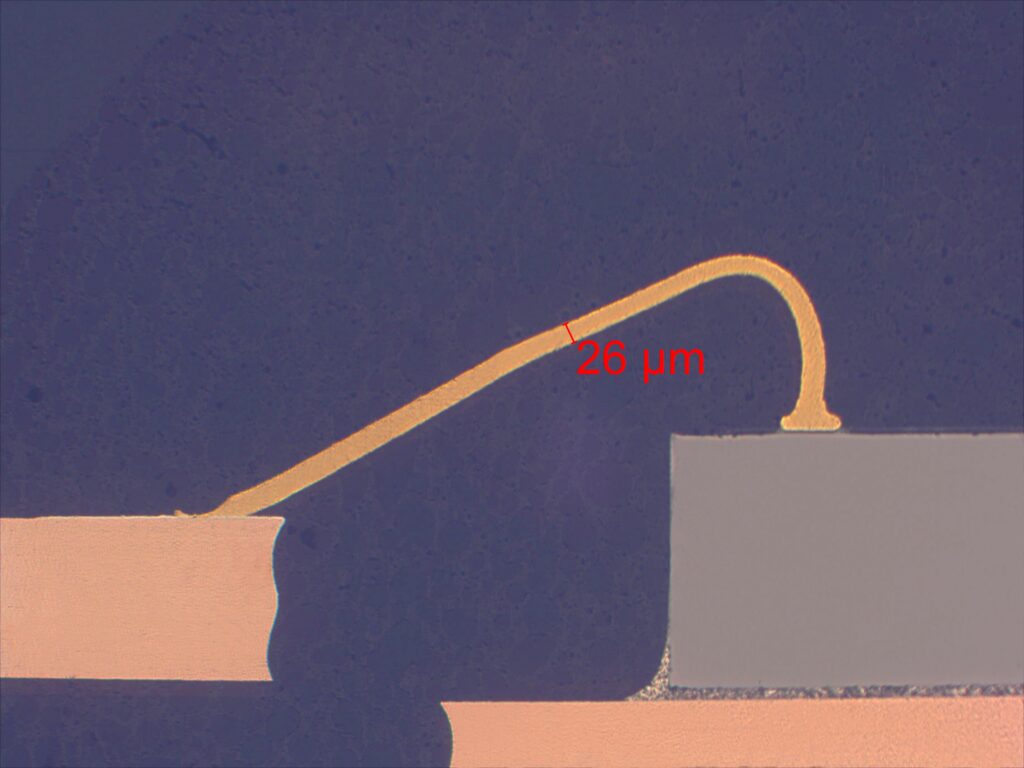

- Bond Pull/Die Shear Testing

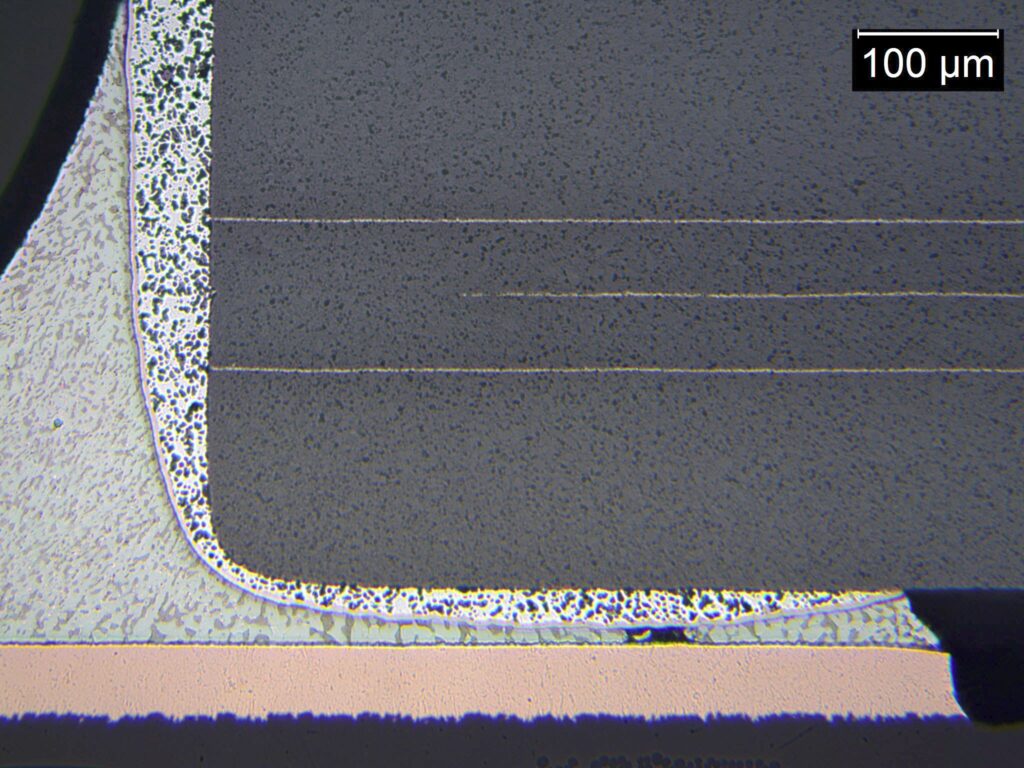

- Microsection Analysis.

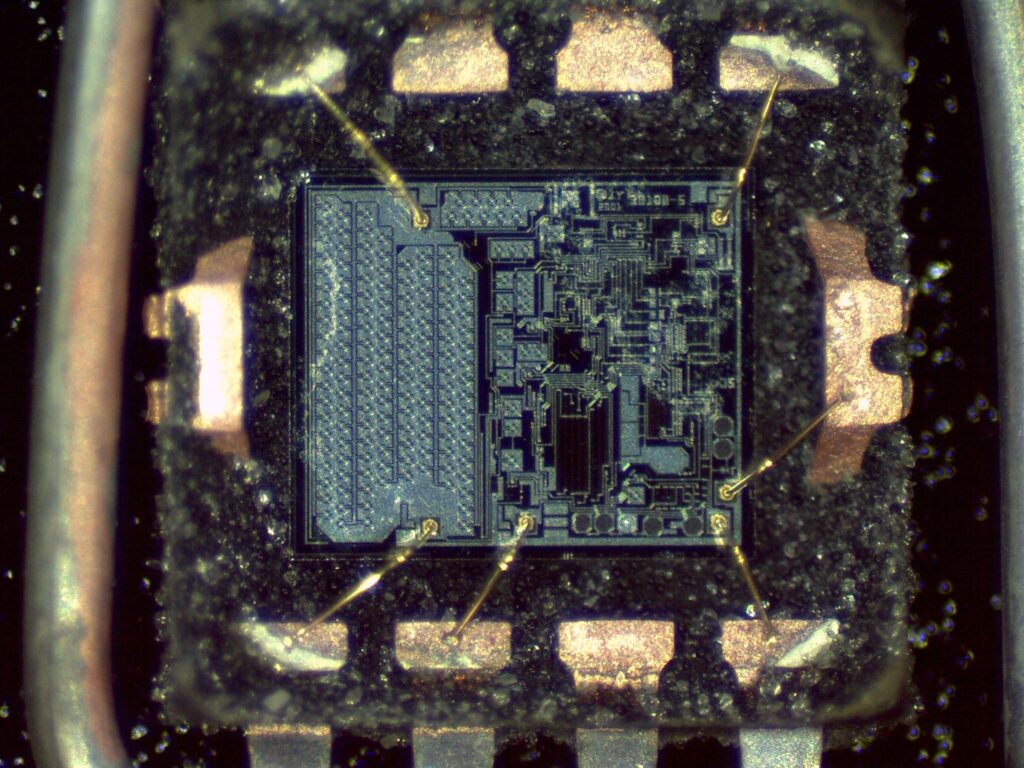

COUNTERFEIT AVOIDANCE TESTING

- Suspect/Fraudulent/Counterfeit Components

- In accordance to the AS6081 standard.

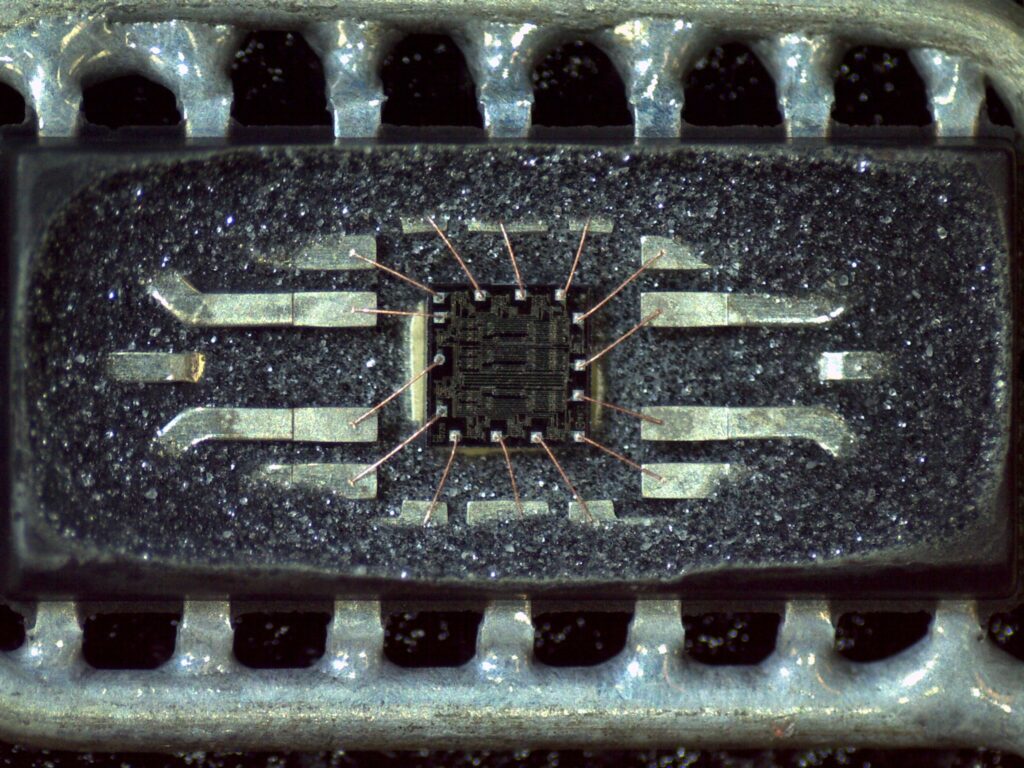

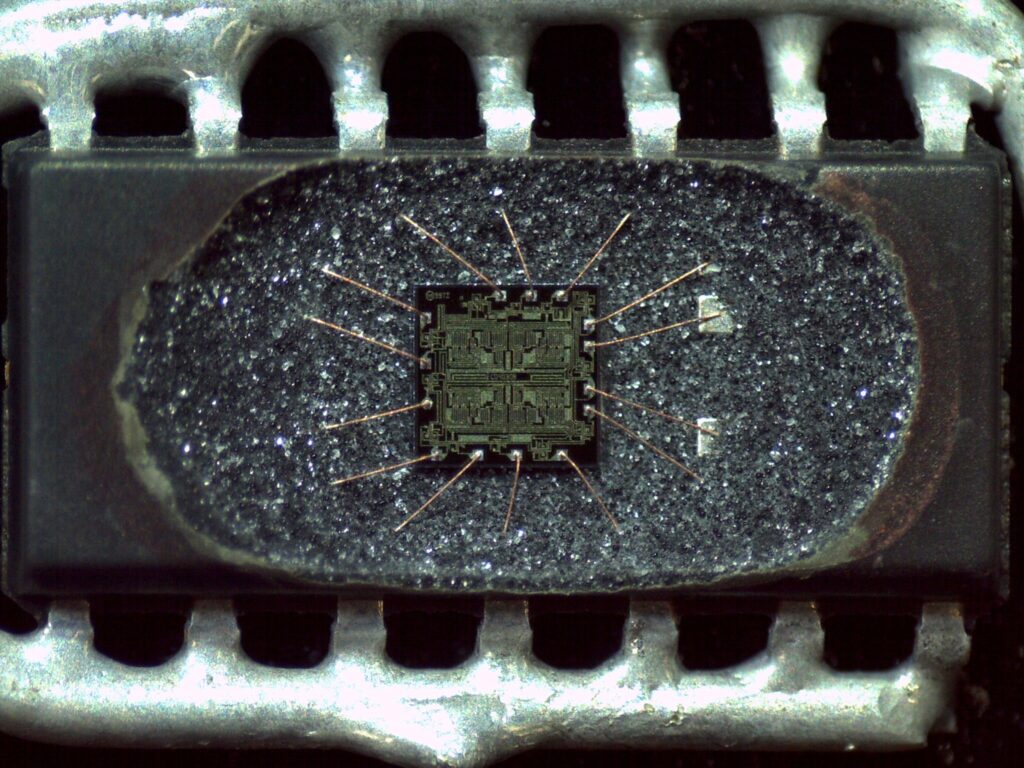

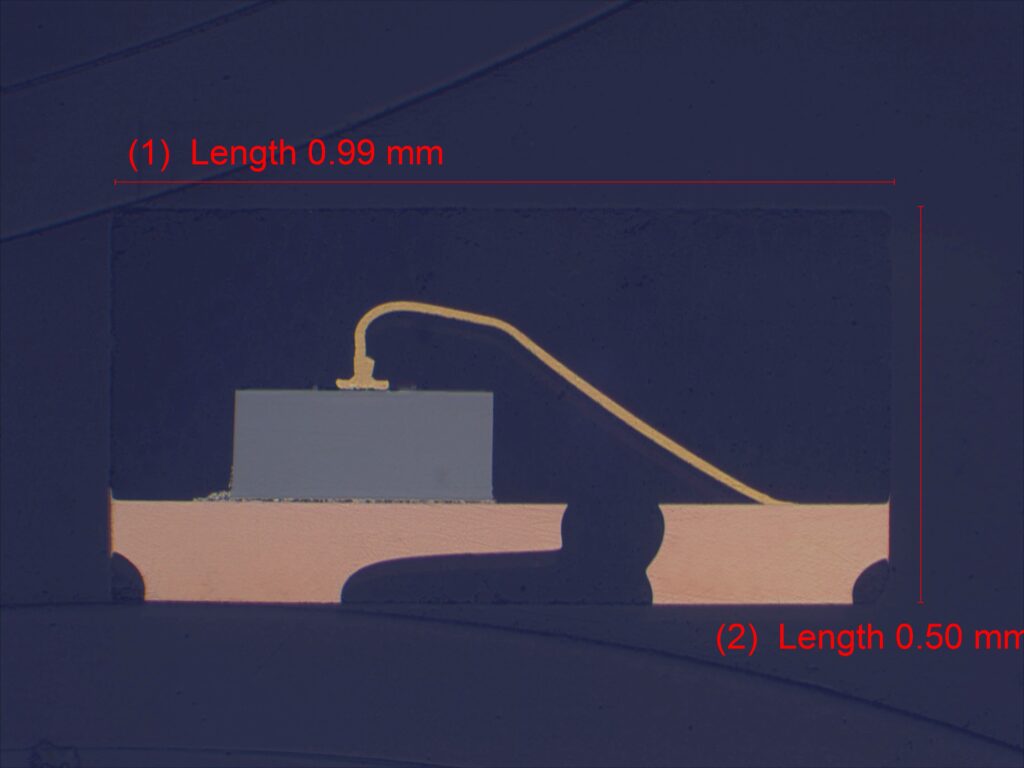

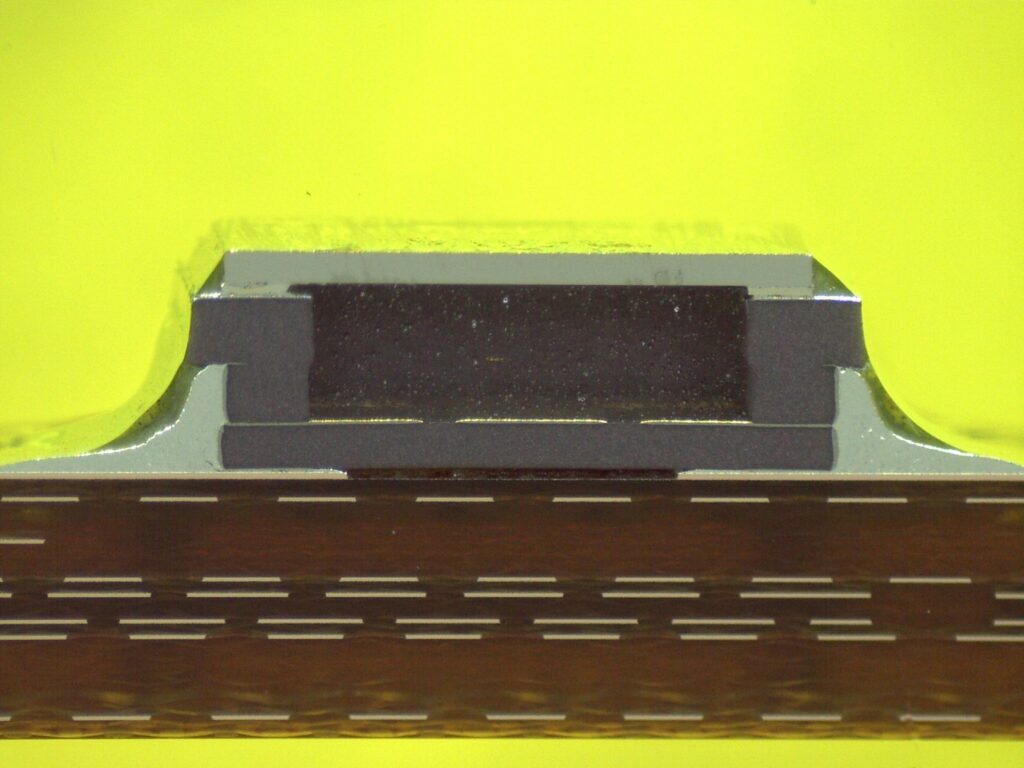

Component Constructional Analysis

Many forms of analysis are carried out in support of our Engineering services such as:

- Constructional Analysis (CA) required prior to the introduction of new types or technologies into component lists.

- Destructive Physical Analysis (DPA) to assure that flight standard components fully meet specified requirements.

- Failure Analysis (FA) to identify failures and root causes.

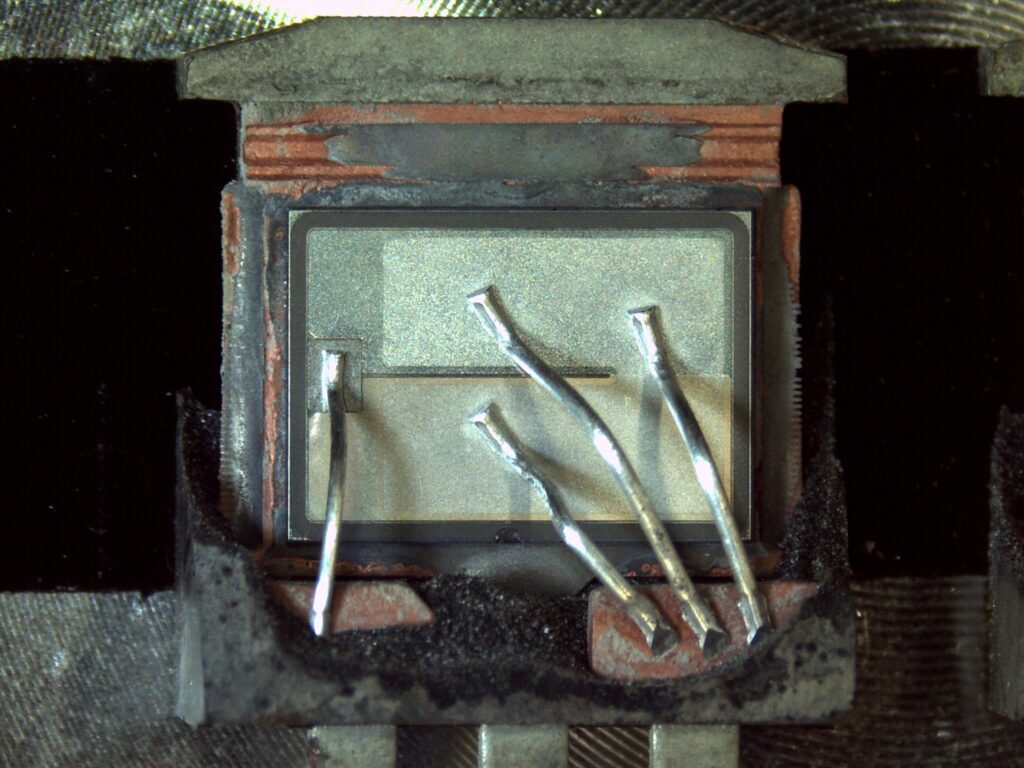

Verification of SMT Assemblies (Solder Verification)

The ESA ECSS Standards require all component types selected for use within Space hardware be verified as acceptable prior to placement. Central to this activity is the requirement for samples of assembled candidate types to be microsectioned to a very high level of precision and quality of finish. The Spur Electron Laboratory is one of the few Laboratories in Europe recommended by ESA to perform this activity.

Failure Investigations and Specialist Studies

Spur Electron Engineers and Laboratory Technicians have gained an enviable reputation for extremely high quality investigative analysis for customers across the electronics industry Worldwide. Compound Microscope & SEM Analysis Data Sheet